Water Jet Cutter Training

REGISTER WITH OMAX

To get access to the necessary software and training videos, you'll need to register for access to the Omax site at

https://authsupport.omax.com/user/register

You'll be asked for two serial numbers for our machine:

- Table serial number: S15085019

- Pump serial number: P210008

- and a zip code: 70118

Select "Create Account" and provide your tulane.edu address and a password with the usual mix of uppercase, lowercase, number and punctuation.

You'll receive an e-mail requesting confirmation; open it and "activate" your account.

If you have trouble gaining access, send a note to andrew.steinhebel@omax.com

INSTALL THE OMAX SOFTWARE

In order to design the part you'll make during hands-on training, you'll need some software on your computer. It runs only on Windows 10. Once you can login to the Omax site with your new account, go to

https://resource-downloads.omax.com/Software

and login again. You'll get a page that lets you download the Omax software, called IntelliMAX.

On the pull-down,

- select Intelli-MAX

- then GlobalMAX

- then Windows 10 (it's the only choice)

- then Released

- and finally English.

You should see a download arrow that looks like an arrow pointing down from a cloud. Click on it, and a 482M zip file file will transfer; extract it and see a single ~494M Application in the directory. Double click to install. The usual "Software Installation Wizard" will pop up; click Next, Next and "Configure as an offline / desktop PC" Accept the license and the default installation directory.

After a restart, there will be a desktop icon for Omax MAKE. Launch it and follow these instructions: File:Registering IntelliMAX Software Online-1.pdf (They are a bit out of date; registration is done completely online rather than with the phone call referenced in the handout.)

WATCH THE TRAINING VIDEOS AND TAKE A QUIZ

You're ready to start. Go to

https://elearning.omax.com/course/view.php?id=39

and watch the following videos to learn about the water jet machining process:

- Introduction to the MAXIEM JetMachining Center

- The Steps Involved in Making Parts

- Introduction to Intelli-MAX LAYOUT

- Step 1: Create a Drawing File

- Step 2: Assign Machining Qualities

- Step 3: Clean the Drawing

- Step 4: Add Path Elements to the Drawing

- Step 5: Create a Machine Tool Path File

- Introduction to Intelli-MAX MAKE

- Operator Safety

- Step 6: Start Up the Machine (MAXIEM Gen 2)

- Step 7: Configure Machine Settings

- Step 8: Open and Configure a Kerf Check File

- Step 9: Load and Clamp the Material

- Step 10: Cut the Kerf Check Part

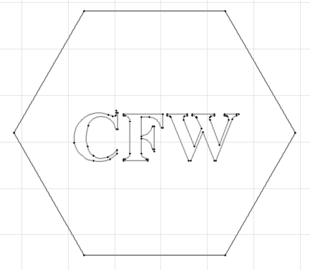

To complete this section, use LAYOUT to design a part, including a tab, like on the right. Note that you can also import .dxf and .svg files into LAYOUT so your experience with Fusion360 and Inkscape will help you a lot.

Save your .dxf file on a USB drive.

HANDS ON TRAINING

Contact a training Fab Tech to schedule an appointment. A list of approved Fab Techs is available in the MakerSpace.

Bring your designed part, stored in .dxf format, on a USB drive. Your instructor will guide you through these steps on our GlobalMax water jet cutter. The goal of the hands-on training is to ensure that there's no injury to people, no damage to the machine, and successful completion of a widget.

- Safety topics and orange card

- Materials that we use, and what we have on hand

- Turn-on sequence (warm water flush)

- How to clamp

- How to load garnet

- How to clear the garnet tube

- Set the z-axis standoff height in AT LEAST two locations

- “Home” the machine and do a dry run of the cutting path

- Importance of “pause” button

- How to recover from a fault (reset) initiated by your trainer

- Make the part

- Record hours, water pressures on log page

- Shut-down sequence.

Your trainer will give you access to the water jet cutter through your RFID card.