Asher Burkin: Difference between revisions

No edit summary |

|||

| Line 49: | Line 49: | ||

[[File:Titan 2.jpg|300px|]] | [[File:Titan 2.jpg|300px|]] | ||

== = | |||

===Water Jet=== | |||

I was helping with a project to cut this 1 inch thick, cold rolled slab of steel, into a new base to hold a vice. The entire operation took around 45 minutes. The garnet container needed to be refilled over 10 times and I was constantly checking the orientation of the the water jet cutter. In setting up the program, I had to take into account the kerf of the water as the holes and size of the base needed to run true to the design. I ran a very slow cut for this operation to ensure the the deflection of the water, as it first goes through the steel, does not curve too much through the cut. | I was helping with a project to cut this 1 inch thick, cold rolled slab of steel, into a new base to hold a vice. The entire operation took around 45 minutes. The garnet container needed to be refilled over 10 times and I was constantly checking the orientation of the the water jet cutter. In setting up the program, I had to take into account the kerf of the water as the holes and size of the base needed to run true to the design. I ran a very slow cut for this operation to ensure the the deflection of the water, as it first goes through the steel, does not curve too much through the cut. | ||

Revision as of 21:44, 23 November 2021

MakerSpace Fabrication Technician

Email: aburkin@tulane.edu

Major: Engineering Physics

Certificate Mechanical Engineering

LinkedIn: in/asherburkin

Profile

Maker Skills

- Machines - CNC Mill, CNC LatheOMAX Water Jet, 3D Printing (Extrusion/SLA), Laser Cutter (Vector/Raster)

- 3D Design - Solidworks, AutoDesk Fusion 360, AutoDesk MeshMixer

- Finite Element Analysis - AutoDesk Fusion 360

- Graphics - Inkscape

- Programming - Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), MATLAB, Intelli-MAX LAYOUT, Intelli-MAX MAKE, Cura

Projects

CNC Mill

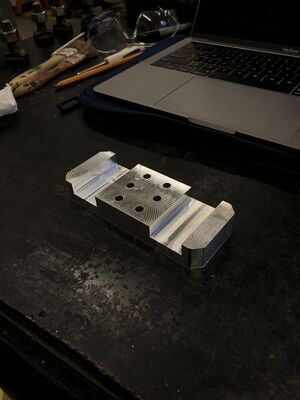

This is the second piece I milled from the Titans of CNC course.

Water Jet

I was helping with a project to cut this 1 inch thick, cold rolled slab of steel, into a new base to hold a vice. The entire operation took around 45 minutes. The garnet container needed to be refilled over 10 times and I was constantly checking the orientation of the the water jet cutter. In setting up the program, I had to take into account the kerf of the water as the holes and size of the base needed to run true to the design. I ran a very slow cut for this operation to ensure the the deflection of the water, as it first goes through the steel, does not curve too much through the cut.