Glass Bead Abrasive Blast Cabinet: Difference between revisions

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

== | For information on safety and [[PPE]] requirements for each machine in the MakerSpace, see the [[Job Hazard Analysis]] forms. | ||

[[File: | |||

This is an | ==Abrasive Blast Cabinet== | ||

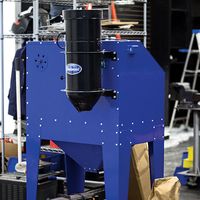

[[File: Eastwood-Dust-Collector.jpg|200px|thumb|right|Dust Collector]] | |||

[[File: Eastwood-Blast-Cabinet.jpg|200px|thumb|center|Abrasive Blast Cabinet]] | |||

This is an enclosed sandblaster that uses compressed air to blast a stream of abrasive material at your workpiece. | |||

===Machine Info=== | ===Machine Info=== | ||

This machine is | This machine is an Eastwood Model 20027 with an Eastwood Model 30998 Dust Collector attached. | ||

[http://makerspace.tulane.edu/index.php/File: | |||

The manuals can be found here [http://makerspace.tulane.edu/index.php/File:Eastwood_blast_cabinet_20027.pdf Blast cabinet] | |||

[http://makerspace.tulane.edu/index.php/File:Eastwood_dust_collector_30998.pdf Dust collector] | |||

ALWAYS use the dust collection system when you're using the blast cabinet. The dust collector on/off switch is a round red button on the top part of the black cylinder. You will hear the vacuum start as soon as the button is pressed, and a red light will be visible in the button. The air hose on the front of the cabinet needs to be connected to the compressed air line mounted on the column in back of the cabinet. Be sure the air supply valve is in the ON position, and that the pressure gauge shows ~100 PSI. | |||

After each extended (10 or more minutes) session, use a plastic container to catch the material that's collected at the bottom of the vacuum dust collection system. Open the door at the bottom of the black cylinder, holding the container right below the door. Bang on the black cylinder a couple of times to release all the trapped abrasive media. Re-latch the door, and recycle the abrasive media you have collected back into the blast cabinet. | |||

Two types of abrasive material are available: glass beads from recycled bottles, and walnut shells. Glass beads are used to produce a matte finish on metal parts, and they are effective in removing rust. They can also be used to remove the gloss from PLA-printed objects, to ensure better paint adhesion. Walnut shells are for paint removal and polishing on soft metals or plastics. Ask a Fab Tech for help before exchanging media in the hopper. | |||

[[PPE]] instructions can be found XXXX. | |||

Replacement | Replacement media for the blast cabinet comes from Harbor Freight: | ||

[http://www.harborfreight.com/25-lbs-fine-grade-walnut-shell-blast-media-92155.html Walnut shells] | |||

[http://www.harborfreight.com/50-lbs-glass-bead-80-grit-abrasive-media-61874.html Glass bead] | |||

or Grainger or Fastenal. | |||

Latest revision as of 18:04, 13 April 2022

For information on safety and PPE requirements for each machine in the MakerSpace, see the Job Hazard Analysis forms.

Abrasive Blast Cabinet

This is an enclosed sandblaster that uses compressed air to blast a stream of abrasive material at your workpiece.

Machine Info

This machine is an Eastwood Model 20027 with an Eastwood Model 30998 Dust Collector attached.

The manuals can be found here Blast cabinet Dust collector

ALWAYS use the dust collection system when you're using the blast cabinet. The dust collector on/off switch is a round red button on the top part of the black cylinder. You will hear the vacuum start as soon as the button is pressed, and a red light will be visible in the button. The air hose on the front of the cabinet needs to be connected to the compressed air line mounted on the column in back of the cabinet. Be sure the air supply valve is in the ON position, and that the pressure gauge shows ~100 PSI.

After each extended (10 or more minutes) session, use a plastic container to catch the material that's collected at the bottom of the vacuum dust collection system. Open the door at the bottom of the black cylinder, holding the container right below the door. Bang on the black cylinder a couple of times to release all the trapped abrasive media. Re-latch the door, and recycle the abrasive media you have collected back into the blast cabinet.

Two types of abrasive material are available: glass beads from recycled bottles, and walnut shells. Glass beads are used to produce a matte finish on metal parts, and they are effective in removing rust. They can also be used to remove the gloss from PLA-printed objects, to ensure better paint adhesion. Walnut shells are for paint removal and polishing on soft metals or plastics. Ask a Fab Tech for help before exchanging media in the hopper.

PPE instructions can be found XXXX.

Replacement media for the blast cabinet comes from Harbor Freight: Walnut shells Glass bead or Grainger or Fastenal.