MakerSpace Access: Difference between revisions

(→Access) |

|||

| (254 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

==Location== | ==Location== | ||

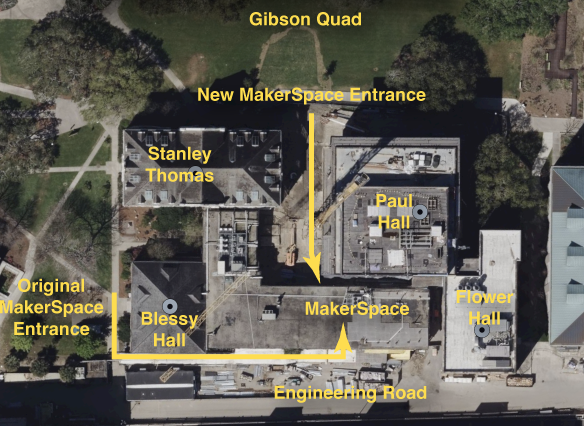

The Scot Ackerman MakerSpace is | The Scot Ackerman MakerSpace can now be accessed via a new entrance just off of Gibson Quad. The new door is in the courtyard between Paul Hall and Stanley Thomas. | ||

[[File: | |||

[[File:MakerSpaceLocationMap_newDoor_2024.png|900px]] | |||

(source: Google Earth) | (source: Google Earth) | ||

The rear door, with the Splash card reader, is locked but provides access to our staff. | <!--- The rear door, with the Splash card reader, is locked but provides access to our staff. ---> | ||

Our [https://en.wikipedia.org/wiki/Maidenhead_Locator_System Maidenhead grid locator] is [https://aprs.fi/#!addr=EL49WW54LV EL49WW54LV] | Our [https://en.wikipedia.org/wiki/Maidenhead_Locator_System Maidenhead grid locator] is [https://aprs.fi/#!addr=EL49WW54LV EL49WW54LV] | ||

| Line 23: | Line 24: | ||

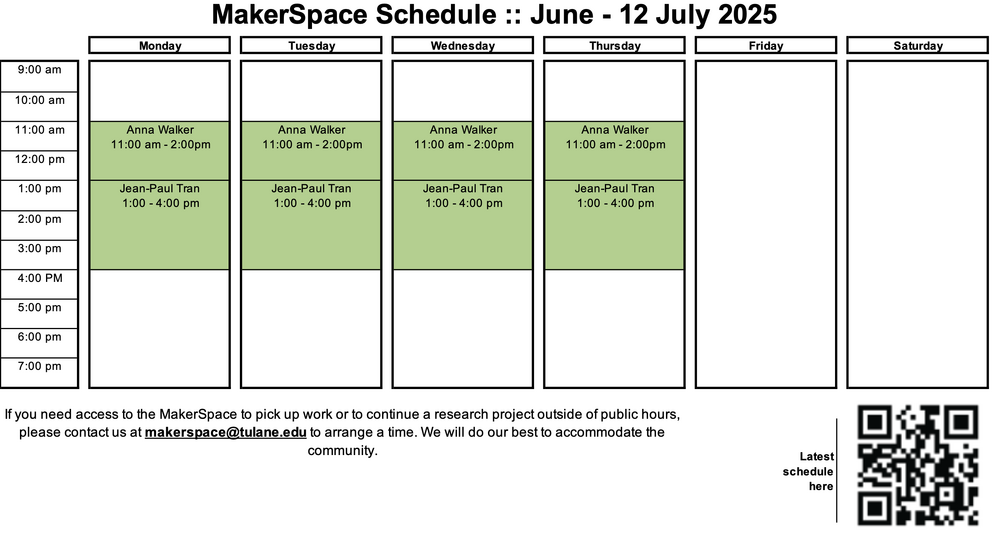

==Hours of Operation== | |||

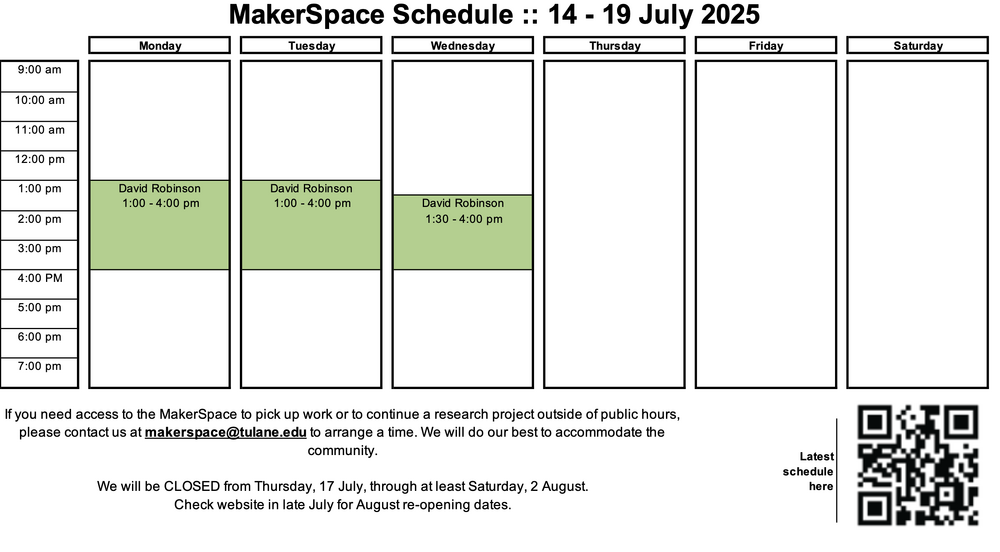

'''''Change of plans! | |||

We will be open Monday, 14 July, through Wednesday, 16 July, then CLOSED from Thursday, 17 July, through the end of the month. | |||

Please check back here in late July for August re-opening dates. This schedule is subject to change.''''' | |||

[[File:MakerSpaceSchedule_juneJuly2025.png||1000px]] | |||

[[File: | [[File:MakerSpaceSchedule_jul2025_1a.png||1000px]] | ||

Please re-check this page often for updated schedules and join the LISTSERV below for announcements. | |||

We use a LISTSERV mailing list for contacting MakerSpace users, all users are added to it automatically. Instructions to send mail, read archives, or unsubscribe from the LISTSERV are [http://makerspace.tulane.edu/index.php/File:LISTSERV_instructions.doc here]. | We use a LISTSERV mailing list for contacting MakerSpace users, all users are added to it automatically. Instructions to send mail, read archives, or unsubscribe from the LISTSERV are [http://makerspace.tulane.edu/index.php/File:LISTSERV_instructions.doc here]. | ||

| Line 52: | Line 48: | ||

==Training== | ==Training== | ||

Preventing injury to people (and equipment) is our first priority. To do this, users must demonstrate knowledge and competence. Users can earn a "badge" that certifies their competence. The various badges, and the equipment authorized by that badge, can be found under the [[Safety and Manuals]] section. | Preventing injury to people (and equipment) is our first priority. To do this, users must demonstrate knowledge and competence. Users can earn a "badge" that certifies their competence. The various badges, and the equipment authorized by that badge, can be found under the [[Safety, Trainings, and Manuals]] section. | ||

Software skills are needed to operate the CNC tools, the water jet and laser cutters, and the 3D printers. We offer [[Training Courses]] during the academic year. | Software skills are needed to operate the CNC tools, the water jet and laser cutters, and the 3D printers. We offer [[Training Courses]] during the academic year. | ||

Along with the | Along with the training, the user's Makerpass app will be required to turn on power to equipment. For example, a user who's completed the requirements for the Metal-1 badge will be allowed to use the drill press, vertical band saw, and some of the portable tools. See [[Machine Access System]] for more information on how the system works. | ||

==Policy on Contracted Projects== | |||

The MakerSpace is a place where students, staff and faculty create useful and esthetic objects. They are "makers" and this means that they realize their designs in a hands-on manner. | |||

Persons who are not members of the Tulane community (defined by possession of a currently valid Splash card) are not allowed to use any facility in the MakerSpace. | |||

From time to time, a member of the Tulane community may need an object built in the MakerSpace, but may not have the skill to build it. They will approach a Ninja for help, offering to pay for time and materials. This policy defines the process and rules for that transaction. | |||

1. The first step is a drawing and a bill of materials, prepared by the client in consultation with the Ninja who is willing to undertake the project. The Ninja also provides a written time-line and estimate of labor cost to the client. The drawing, bill of materials, and labor cost estimate are forwarded by the client to makerspace@tulane.edu | |||

2. If the job is accepted by MakerSpace management, the client will be asked to create an Interdepartmental Transfer (IT) so that the MakerSpace account can be credited. An overhead charge of 20% will be added. | |||

3. Trivial materials (PLA filament, 1/8" plywood, fasteners) are provided as part of the overhead charge. Any other materials are to be provided by the client. Clients who want to use existing MakerSpace material stock will be charged for the replacement value found at mcmaster.com. Scheduling is negotiated between the Ninja and client, who needs to respect the status of the Ninja as a student undertaking this work in extracurricular time. | |||

If the scope of the project changes during the build phase, or the labor cost estimate proves to be inaccurate, a collegial exchange of e-mails including makerspace@tulane.edu is the preferred method of keeping all parties informed as the problem moves toward resolution. | |||

When the project is completed, the IT will be closed out and all parties informed of the final cost. | |||

current as of 10/5/2017 | |||

makerspace@tulane.edu | |||

==For Grant Writers== | ==For Grant Writers== | ||

The School of Science and Engineering | The School of Science and Engineering hosts the University's state-of-the-art Scot Ackerman MakerSpace, located on Engineering Road in the heart of the School's complex. This facility is open and free of charge to all Tulane students, staff, and faculty, and provides access to and training for rapid prototyping machines, including wood shop, and electronics laboratory. | ||

The main floor (2,896 square feet) houses a 30" x 60" water jet cutter, 13 3-D filament printers, 3 laser cutters, a 4-axis CNC milling machine, a CNC lathe, a CNC router | The main floor (2,896 square feet) houses a 30" x 60" water jet cutter, 13 3-D filament printers, 3 laser cutters, a 4-axis CNC milling machine, a CNC lathe, a CNC router, a fully-equipped machine shop, and a supply storage area. | ||

The wood shop (730 square feet) has a table saw, sliding miter saw, power sanders, band saws, and a drill press in addition to assembly space. A closet holds 3 high-resolution 3-D resin printers. | The wood shop (730 square feet) has a table saw, sliding miter saw, power sanders, band saws, and a drill press in addition to assembly space. A closet holds 3 high-resolution 3-D resin printers. | ||

Latest revision as of 16:00, 11 July 2025

Location

The Scot Ackerman MakerSpace can now be accessed via a new entrance just off of Gibson Quad. The new door is in the courtyard between Paul Hall and Stanley Thomas.

(source: Google Earth)

Our Maidenhead grid locator is EL49WW54LV

Our what3words grid is parts.leaps.darkest

Our entrance, shown on this Google Map, is at latitude 29.9370740, longitude -90.1210170 or you can search for WVPH+RH on Google Maps.

Contact

Email: makerspace@tulane.edu

Facebook: https://www.facebook.com/MakerSpace.Tulane/

Hours of Operation

Change of plans!

We will be open Monday, 14 July, through Wednesday, 16 July, then CLOSED from Thursday, 17 July, through the end of the month.

Please check back here in late July for August re-opening dates. This schedule is subject to change.

Please re-check this page often for updated schedules and join the LISTSERV below for announcements.

We use a LISTSERV mailing list for contacting MakerSpace users, all users are added to it automatically. Instructions to send mail, read archives, or unsubscribe from the LISTSERV are here.

Training

Preventing injury to people (and equipment) is our first priority. To do this, users must demonstrate knowledge and competence. Users can earn a "badge" that certifies their competence. The various badges, and the equipment authorized by that badge, can be found under the Safety, Trainings, and Manuals section.

Software skills are needed to operate the CNC tools, the water jet and laser cutters, and the 3D printers. We offer Training Courses during the academic year.

Along with the training, the user's Makerpass app will be required to turn on power to equipment. For example, a user who's completed the requirements for the Metal-1 badge will be allowed to use the drill press, vertical band saw, and some of the portable tools. See Machine Access System for more information on how the system works.

Policy on Contracted Projects

The MakerSpace is a place where students, staff and faculty create useful and esthetic objects. They are "makers" and this means that they realize their designs in a hands-on manner.

Persons who are not members of the Tulane community (defined by possession of a currently valid Splash card) are not allowed to use any facility in the MakerSpace.

From time to time, a member of the Tulane community may need an object built in the MakerSpace, but may not have the skill to build it. They will approach a Ninja for help, offering to pay for time and materials. This policy defines the process and rules for that transaction.

1. The first step is a drawing and a bill of materials, prepared by the client in consultation with the Ninja who is willing to undertake the project. The Ninja also provides a written time-line and estimate of labor cost to the client. The drawing, bill of materials, and labor cost estimate are forwarded by the client to makerspace@tulane.edu

2. If the job is accepted by MakerSpace management, the client will be asked to create an Interdepartmental Transfer (IT) so that the MakerSpace account can be credited. An overhead charge of 20% will be added.

3. Trivial materials (PLA filament, 1/8" plywood, fasteners) are provided as part of the overhead charge. Any other materials are to be provided by the client. Clients who want to use existing MakerSpace material stock will be charged for the replacement value found at mcmaster.com. Scheduling is negotiated between the Ninja and client, who needs to respect the status of the Ninja as a student undertaking this work in extracurricular time.

If the scope of the project changes during the build phase, or the labor cost estimate proves to be inaccurate, a collegial exchange of e-mails including makerspace@tulane.edu is the preferred method of keeping all parties informed as the problem moves toward resolution.

When the project is completed, the IT will be closed out and all parties informed of the final cost.

current as of 10/5/2017 makerspace@tulane.edu

For Grant Writers

The School of Science and Engineering hosts the University's state-of-the-art Scot Ackerman MakerSpace, located on Engineering Road in the heart of the School's complex. This facility is open and free of charge to all Tulane students, staff, and faculty, and provides access to and training for rapid prototyping machines, including wood shop, and electronics laboratory.

The main floor (2,896 square feet) houses a 30" x 60" water jet cutter, 13 3-D filament printers, 3 laser cutters, a 4-axis CNC milling machine, a CNC lathe, a CNC router, a fully-equipped machine shop, and a supply storage area.

The wood shop (730 square feet) has a table saw, sliding miter saw, power sanders, band saws, and a drill press in addition to assembly space. A closet holds 3 high-resolution 3-D resin printers.

The Gallery for Ideas, Design and Strategies on the mezzanine (923 square feet) has design and conference space.

The Product Development and Innovation Room (1,026 square feet) has dedicated benches for in-progress projects, a classroom area for tutorials, training and communication, a demonstration area with a Clausing lathe and Bridgeport milling machine, and an electronics fabrication studio.

Multiple staff members are on-hand for 45 hours per week to assist in training and project design, and computers and design software are available on-site for project design and development.