MakerSpace Access

Location

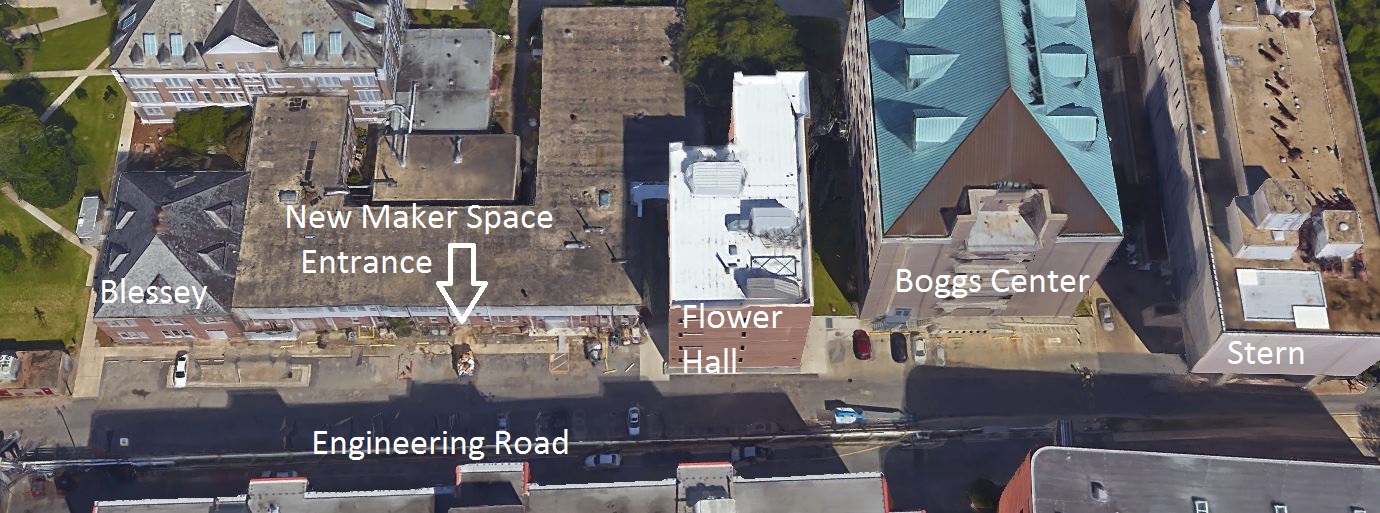

We're on Engineering Road, along the boundary between the Tulane and Loyola campuses

Contact

Email: makerspace@tulane.edu

Facebook: https://www.facebook.com/MakerSpace.Tulane/

Access

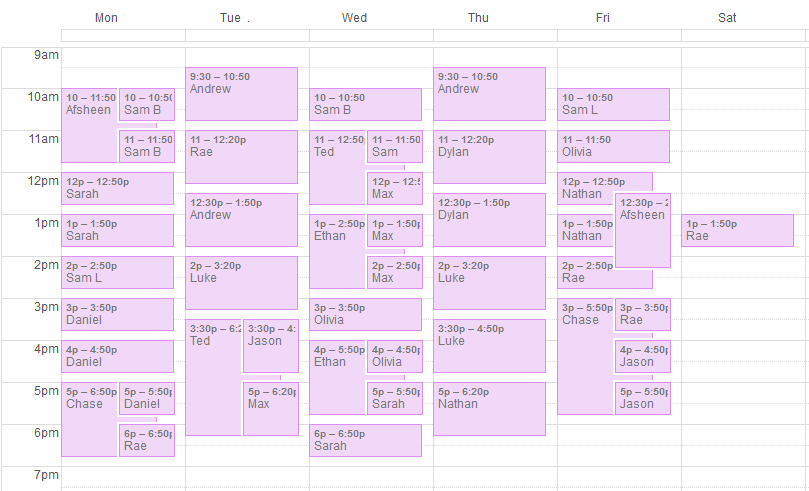

We're open ~8 hours/day Monday through Friday when classes are in session. And on Saturday, we're briefly open in the afternoon so users can re-load or pick up 3d prints. This year, we'll also have limited daily hours during breaks and vacations.

The Maker Ninjas (student workers) and faculty members responsible for the operation of the MakerSpace are listed under People, and users with special requests are encouraged to contact them.

Users with special need to access the Maker Space should get in touch with the Director or one of the Advisors, who are listed under People

We use a LISTSERV mailing list for contacting MakerSpace users, all users are added to it automatically. Instructions to send mail, read archives, or unsubscribe from the LISTSERV are here.

Training

Preventing injury to people (and equipment) is our first priority. To do this, users must demonstrate knowledge and competence. Users can earn a "badge" that certifies their competence. The various badges, and the equipment authorized by that badge, can be found under the Safety and Manuals section.

Along with the badge, the user's RFID card will be recognized to turn on power to equipment. For example, a user who's completed the requirements for the Metal-1 badge will be allowed to use the drill press, vertical band saw, and some of the portable tools. See Machine Access System for more information on how the system works.

For Grant Writers

The School of Science and Engineering also houses the brand new, state-of-the-art, 4100-square-foot Tulane MakerSpace, located in the heart of the Science and Engineering Complex. This facility is open and free of charge to all University members, and provides access to and training for rapid prototyping machines, including 7 3-D printers, 2 high-resolution 3-D printers, 2 laser cutters, a 4-axis CNC milling machine, a CNC lathe, and a fully-equipped machine shop, wood shop, and electronics laboratory. Multiple staff members are on-hand up to 50 hours per week to assist in training and project design, and computers and design software are available on-site for project design and development.