Bambu P1 Series

The P1 series are our newest fleet of FDM printers, and specialize in speed. Because of this, they are a great choice for rapid prototyping.

The speed of the P1 series allows for small prints to be completed in a matter of minutes, our 3D Benchy benchmark print is completed in under 14 minutes on a P1 series printer, while on an Creality Ender 3 it usually takes 2 hours.

Printing

To print to a P1 series printer you must slice and send your file on the 3D printing PC. Printing with Orca Slicer

A previous print can be rerun using the build in file system, select the folder icon on the left, open the cache folder, and select the name of your previous print.

Design Considerations

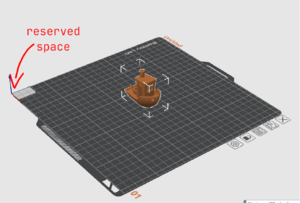

The P1 series features a filament cutting attachment for its hotend. The front-left portion of the buildplate is reserved for this function. In Orca Slicer it is not possible to position objects in this area and will give an error.

Buildplate

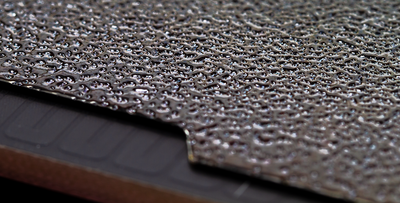

Our P1 series printers feature textured PEI Beds. These allow for good adhesion and easy removal of objects.

To remove a print from the bed, lift the front edge up, and grab the rear tab with your other hand. only hold the plate via the tabs, hand oils ruin the bed!.

Flexing the bed both ways will detach the print from the bed.