Chase Schober: Difference between revisions

No edit summary |

No edit summary |

||

| Line 15: | Line 15: | ||

*'''CNC Mill''' | *'''CNC Mill''' | ||

Over the summer of 2017, I logged over 300 hours on the Tormach PCNC 770 mill. After training with the available stock in the MakerSpace, I began to machine parts for various research groups on campus. These custom parts varied significantly in complexity and required tolerance. Here are some of the more comprehensive projects that I worked on with a description of their process and purpose. | Over the summer of 2017, I logged over 300 hours on the Tormach PCNC 770 mill. After training with the available stock in the MakerSpace, I began to machine parts for various research groups on campus. These custom parts varied significantly in complexity and required tolerance. Here are some of the more comprehensive projects that I worked on with a description of their process and purpose. | ||

Jason Schuster Parts: | Jason Schuster Parts: | ||

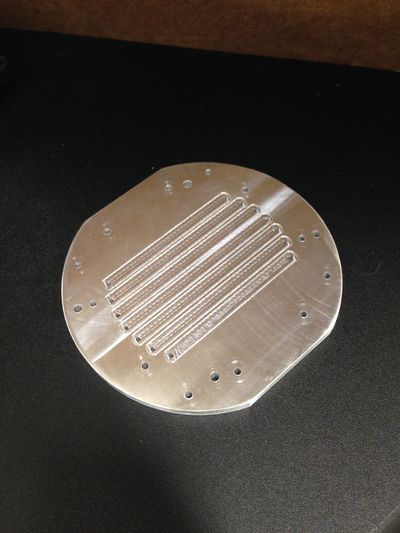

Jason approached me with the engineering plans for an apparatus to assist in his bio-medical research. I took the fusion models that he created, and machined the four "slider" parts and then the stamp base using the Tormach PCNC 770. Becuase of the locomotive nature of the part, the tolerances had to be within ± .002". | |||

[[File:Chase Schuster 1.jpeg|400px]] | [[File:Chase Schuster 1.jpeg|400px]] | ||

Revision as of 18:49, 4 September 2017

MakerSpace Ninja

Email: cschober@tulane.edu

Phone: (504) 722-9514

Major: Engineering Physics

Projects

- CNC Mill

Over the summer of 2017, I logged over 300 hours on the Tormach PCNC 770 mill. After training with the available stock in the MakerSpace, I began to machine parts for various research groups on campus. These custom parts varied significantly in complexity and required tolerance. Here are some of the more comprehensive projects that I worked on with a description of their process and purpose.

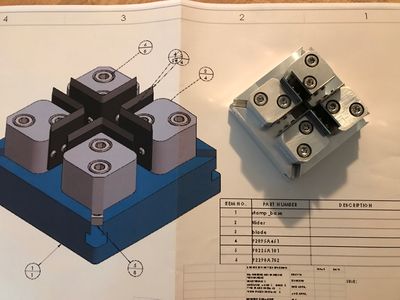

Jason Schuster Parts:

Jason approached me with the engineering plans for an apparatus to assist in his bio-medical research. I took the fusion models that he created, and machined the four "slider" parts and then the stamp base using the Tormach PCNC 770. Becuase of the locomotive nature of the part, the tolerances had to be within ± .002".

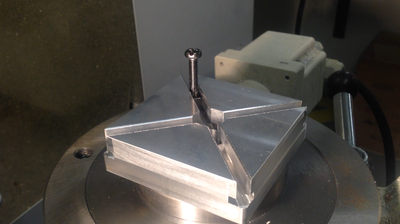

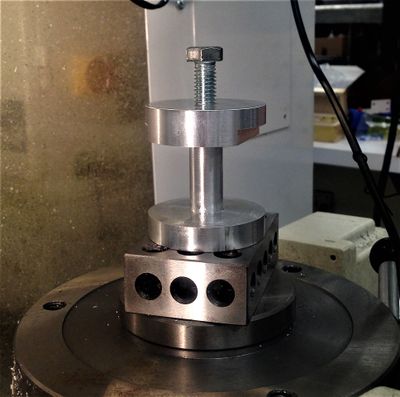

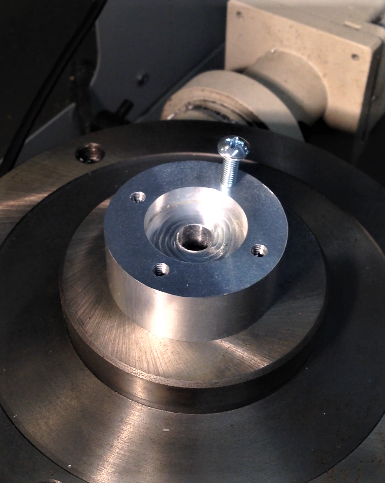

Cryo-Optic Chamber:

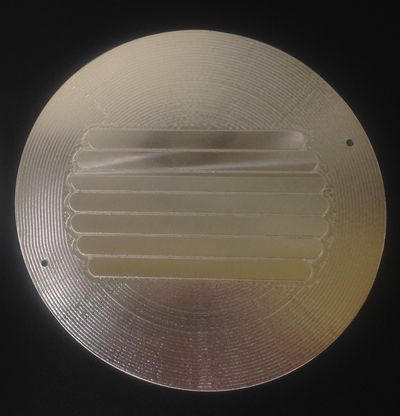

Escarra Research Parts

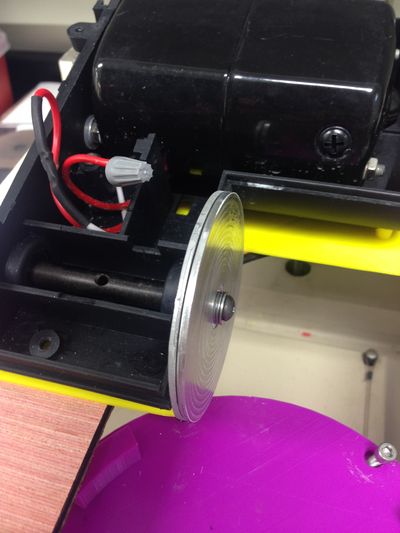

Fidget Spinner:

Dice:

Spinning Army Star

- CNC Lathe

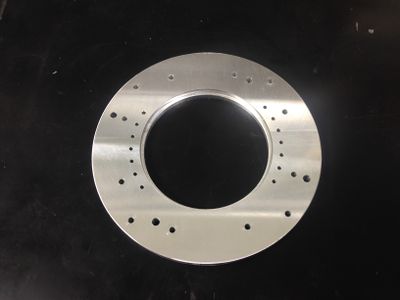

Cryo-Optic Chamber Lid

Jarrod's Parts

- Laser Engraver

Chess Board:

Arduino Enclosure:

Coasters:

Bowling Set: