3D Printing

Looking For How To Print? Check out Printing with Orca Slicer

3D printing is a modern rapid prototyping technique in which a solid object is created through a layered deposition process. 3D printing is referred to as an "additive manufacturing" technique, as instead of taking material away from a stock piece in order to create a desired object, such as in milling or turning manufacturing techniques, the material for the object is added by the printing process. 3D printing techniques make it very simple to quickly create both complex and simple objects.

The 3D printers available in the MakerSpace are all Fused Filament Fabrication (FFF) printers, meaning that to create the desired part, molten polymer (melted plastic) is "extruded" into a thin molten filament, which is deposited in the desired shape. The hot plastic fuses with previously deposited layers, creating the desired part. Due to the nature of molten plastic, FFF 3D printed parts have a degree of "slop" that is difficult to eliminate, so a different manufacturing technique, such as laser cutting or CNC Routing/Milling, is likely necessary for parts that require very high degrees of accuracy.

The Tulane MakerSpace contains Creality Ender and BambuLab P1 and X1 Series 3D printers with heated beds to allow for any extruded 1.75mm filament. ABS filament allows for better finishing effects (such as smoothing), but PLA provides a more rigid part and has has much better adherence to the print bed. There are other advantages and disadvantages to both. Cost is the same (currently ~$18 per kg). The Makerspace currently supplies free PLA for use, other filaments and specific colors should be user supplied.

While ABS and PLA are the most commonly used filaments, many other products exist with special qualities (flexible) or appearance (wood, ceramic). There is a good summary and comparison at MatterHackers. MakerSpace users wishing to try out these filaments should procure them and work with a Fab Tech to load them onto the printer.

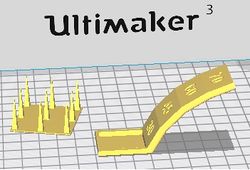

The standard slicing software favored for these printers is Orca Slicer, which allows you to arrange and size your model and set options for the printer to follow. All makerspace FDM printers can be printed to via Orca Slicer.

Available 3D Printers

For information on safety and PPE requirements for each machine in the MakerSpace, see the Job Hazard Analysis forms.

Bambu X1 Series (advanced)

Test Files

Matter Hackers has a collection of test files that are useful after repairing or re-calibrating a printer. Here's another version of the description

File:Matter Hackers 3d printer tests.pdf

These are a great way to compare two different print settings or brands of filament.

File:4 DimmensionalAccuracy.stl

File:7 negative space tolerance test.stl

File:12 retraction performance test.stl

3D Printing Problems

3dVerkstan has a fantastic guide to diagnosing print failures. It is specifically written for Ultimaker printers, but the information applies to any type of 3d printer.

Simplify 3D has created an extremely helpful Print Quality Troubleshooting Guide.

RepRap also has a helpful wiki which contains a Print Troubleshooting Pictorial Guide.