Ben Lewson: Difference between revisions

No edit summary |

(→Bio) |

||

| (12 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

'''Phone:''' (864) 497-1924 | '''Phone:''' (864) 497-1924 | ||

''' | '''LinkedIn:''' [https://www.linkedin.com/in/ben-lewson Ben Lewson] | ||

'''GitHub:''' [https://github.com/PercMain | '''GitHub:''' [https://github.com/PercMain PercussiveMaintenance] | ||

==Profile== | ==Profile== | ||

===Bio=== | ===Bio=== | ||

I'm an | I'm an engineer with a passion for making and design. The MakerSpace has been a great opportunity for me to work on projects ranging from musical electronics, to robotics, to medical devices. I love the fact that the space is open to people from all departments and majors. I've definitely learned more from the unique perspectives of our users than I ever could have on my own. Right now, I'm working on writing a library for generating different geometric patterns on the laser cutter, improving my team's biopsy punch design, outfitting more of our marching band with sound reactive lights, and a visually driven drum synthesizer. Feel free to email me if you want to know more about any of the projects I've worked on, or if you want to learn more about the MakerSpace. Or if you want to see what I'm currently coding, check out my [https://github.com/PercMain GitHub]! | ||

===Projects Portfolio=== | ===Projects Portfolio=== | ||

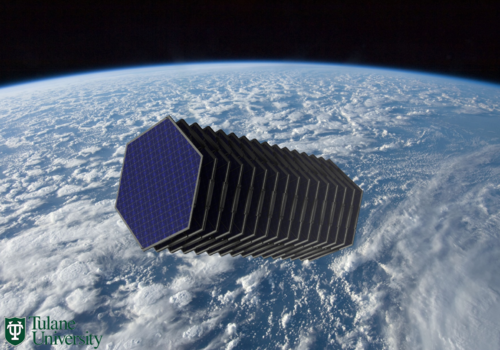

* ''' | *'''NASA Big Idea Challenge: Project Sunflower''' | ||

:'' | :'''Links and Downloads:'''[http://bigidea.nianet.org/wp-content/uploads/2017/02/2017-BIG-Idea-Finalist-Paper_Tulane.pdf Technical Paper] [http://bigidea.nianet.org/wp-content/uploads/2017/02/Tulane-NASA-Big-Idea-Challenge-PPTX-Format-copy.pptx Presentation (Click to Download)] | ||

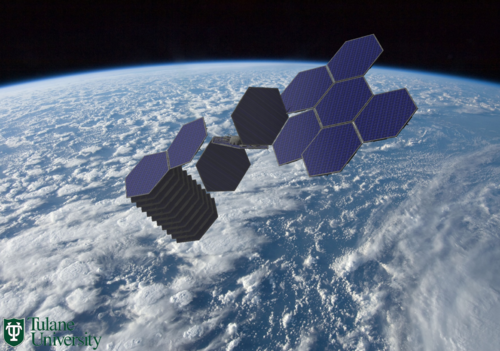

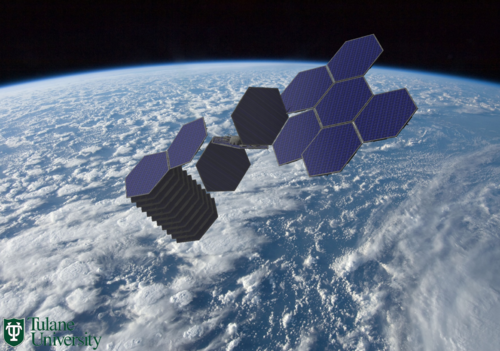

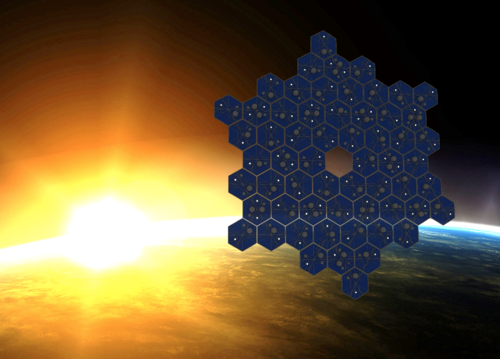

Holy expletive, we won! I'm incredibly grateful for the opportunity to have worked with such creative and talented engineers. I truly can't wait to work with these guys in the future. | |||

The Sunflower is a modular Solar Electric Propulsion (SEP) Tug system designed to transfer cargo from Low Earth Orbit (LEO) to Lunar Distant Retrograde Orbit (LDRO) economically and efficiently. | |||

</ | <div><ul> | ||

<li style="display: inline-block;"> [[File:Sun_render_1.png|thumb|none|500px|Deployment]] </li> | |||

<li style="display: inline-block;"> [[File:Sun_render_2.png|thumb|none|500px|Initial Unfolding]] </li> | |||

<li style="display: inline-block;"> [[File:Sun_render_2.png|thumb|none|500px|Unfolded half-array]] </li> | |||

<li style="display: inline-block;"> [[File:Sunflower_render.png|thumb|none|500px|Fully Assembled in LEO]] </li> | |||

*'''Automated Biopsy Punch''' | *'''Automated Biopsy Punch''' | ||

:''Videos:'' [https://www.youtube.com/watch?v=e3jgSsBuCZ8&feature=youtu.be Assembly Animation] | |||

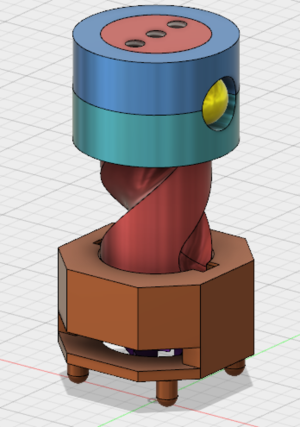

:'''Videos:''' [https://youtu.be/HrbH47rLqYk Assembly Animation Version 2] [https://www.youtube.com/watch?v=7f3ItzSnkTE 4 Axis Machining of Helical Drive] [https://www.youtube.com/watch?v=e3jgSsBuCZ8&feature=youtu.be Assembly Animation Version 1] | |||

The automated biopsy punch solves the problem of the currently time consuming and inconsistent process of taking a punch biopsy for the diagnosis of melanoma and carcinoma. The CMDX Biopsy Team (Sydney Chestler, Ryan Fishel, Perri Levine, and Ben Lewson) have been developing this technology since 2014, for both the Tulane University Novel Technology Challenge and their respective Senior Team Design projects. | |||

<div><ul> | <div><ul> | ||

<li style="display: inline-block;"> [[File:bearing_fit_1.jpeg|thumb|none|300px|Bearing fit on DLP print (Looks good!)]] </li> | |||

<li style="display: inline-block;"> [[File:Dlp_assembly_1.jpeg|thumb|none|300px|DLP printed helical drive mechanism]] </li> | |||

<li style="display: inline-block;"> [[File:Mechanism_V2_1.png|thumb|none|300px|Helix drive mechanism overview]] </li> | |||

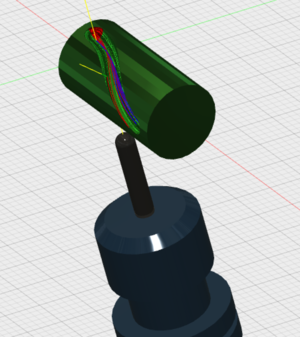

<li style="display: inline-block;"> [[File:4_Axis_CAM_Toolpath_1.png|thumb|none|300px|4 Axis CAM Toolpath for helical drive]] </li> | |||

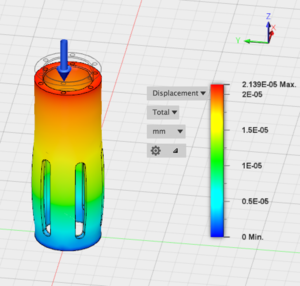

<li style="display: inline-block;"> [[File:FEA_11_22.png|thumb|none|300px|Deflection Analysis of prototype case under typical load]] </li> | |||

<li style="display: inline-block;"> [[File:Biopsy_punch_motor_carrier.JPG|thumb|none|300px|Gear motor mounted in 3D printed casing]] </li> | <li style="display: inline-block;"> [[File:Biopsy_punch_motor_carrier.JPG|thumb|none|300px|Gear motor mounted in 3D printed casing]] </li> | ||

<li style="display: inline-block;"> [[File:Biopsy_punch_bearing_seat.JPG|thumb|none|300px|Needle bearing press-fit into housing]] </li> | <li style="display: inline-block;"> [[File:Biopsy_punch_bearing_seat.JPG|thumb|none|300px|Needle bearing press-fit into housing]] </li> | ||

| Line 33: | Line 43: | ||

<li style="display: inline-block;"> [[File:Biopsy_demo_assembly.JPG|thumb|none|300px|Fully assembled demo model]] </li> | <li style="display: inline-block;"> [[File:Biopsy_demo_assembly.JPG|thumb|none|300px|Fully assembled demo model]] </li> | ||

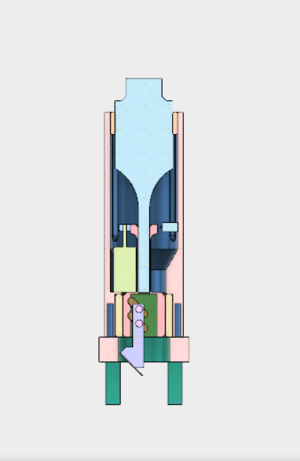

<li style="display: inline-block;"> [[File:biopsy_cross_section_3.png|thumb|none|300px|Cross Section of full CAD model]] </li> | <li style="display: inline-block;"> [[File:biopsy_cross_section_3.png|thumb|none|300px|Cross Section of full CAD model]] </li> | ||

</ul></div> | |||

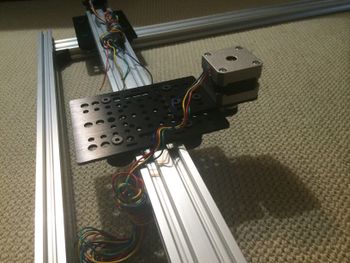

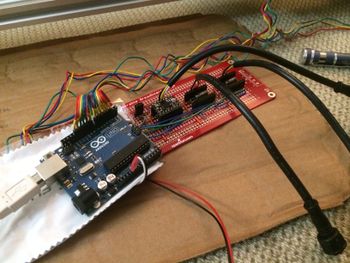

* '''Laser Engraver''' | |||

:'''Videos:''' [https://www.youtube.com/watch?v=IRf76iCyeEw Motion Test] [https://www.youtube.com/watch?v=tyzNq6BTp8U Sample File] [https://www.youtube.com/watch?v=fzyHYCkpCJI Engraving Test] | |||

This is what happens when information about the GRBL embedded CNC controller, the discovery that reasonably high-wattage laser diodes are available cheaply on Amazon, and a few hundred dollars all fall into my lap at the same time. It was a really interesting project that taught me quite a bit about CNC control workflows, powering laser diodes, and the joys of 80-20 aluminum extrusion. | |||

<div><ul> | |||

<li style="display: inline-block;"> [[File:laser_engraver_wood_test_result.JPG|thumb|none|350px|The first successful engraving-a simple geometric pattern in wood]] </li> | |||

<li style="display: inline-block;"> [[File:laser_engraver_x_carriage.JPG|thumb|none|350px|The X-axis carriage of the engraver-Driven by toothed belt and pulley]] </li> | |||

<li style="display: inline-block;"> [[File:Laser_engraver_components_testing.JPG|thumb|none|350px|All the components of the engraver-Motion is functional at this point]] </li> | |||

<li style="display: inline-block;"> [[File:laser_engraver_x_y_assembly.JPG|thumb|none|350px|The X and Y axis with motors mounted-Wires have yet to be sleeved and cut to length]] </li> | |||

<li style="display: inline-block;"> [[File:laser_engraver_stepper_driver_board.JPG|thumb|none|350px|Stepper driver board with 1 driver installed]] </li> | |||

</ul></div> | </ul></div> | ||

*'''Sound Reactive Drum Lights''' | *'''Sound Reactive Drum Lights''' | ||

:''Videos:'' [https://www.youtube.com/watch?v=MgJpYF_W03w Practice Session][https://youtu.be/d_L0McA59r0?t=22s Promotional Video] | |||

:'''Videos:''' [https://www.youtube.com/watch?v=MgJpYF_W03w Practice Session] [https://youtu.be/d_L0McA59r0?t=22s Promotional Video] [https://youtu.be/McHbqsX9GTs Piezo Test] (2017 parade footage coming soon!) | |||

As a proud member of the Tulane University Marching Band from 2014 to 2016, I was incredibly excited for the chance to add sound reactive lighting to our drumline to make our Mardi Gras parades a little more exciting and possibly disorientating. | |||

<div><ul> | <div><ul> | ||

<li style="display: inline-block;"> [[File:drum_lights_in_situ.png|thumb|none| | <li style="display: inline-block;"> [[File:drum_lights_in_situ.png|thumb|none|400px|Lighting array mid performance. The battery is holding up!]] </li> | ||

<li style="display: inline-block;"> [[File:semi_complete_boards.JPG|thumb|none|400px|Semi-complete boards for version 2.]] </li> | |||

<li style="display: inline-block;"> [[File:drum_light_cases.JPG|thumb|none|400px|Cases fresh off the print bed. Now in 2 exciting sherbert flavors!]] </li> | |||

<li style="display: inline-block;"> [[File:drum_lights_in_cases.JPG|thumb|none|400px|Some finished controllers in their cases.]] </li> | |||

</ul></div> | </ul></div> | ||

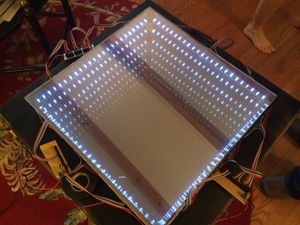

*'''Infinity Table''' | *'''Infinity Table''' | ||

For when you need a side table for your dorm room, but you have a pathological obsession with blinking lights and haven't heard of addressable LED strips yet. | |||

<div><ul> | <div><ul> | ||

<li style="display: inline-block;"> [[File:Infinity_table_light_arrays_test.JPG|thumb|none|300px|All of the light segments powered on for the first time]] </li> | <li style="display: inline-block;"> [[File:Infinity_table_light_arrays_test.JPG|thumb|none|300px|All of the light segments powered on for the first time]] </li> | ||

| Line 55: | Line 87: | ||

*CNC Mill | *CNC Mill | ||

*CNC Lathe | |||

*Analog Electronics | *Analog Electronics | ||

| Line 60: | Line 94: | ||

*Microcontrollers | *Microcontrollers | ||

* | *Machining | ||

* | *Design for Manufacture | ||

* | *3D Design - [[Solidworks]], [[AutoDesk Fusion 360]], [[Cura]], [[AutoDesk Print Studio]] | ||

* | *Vector Graphics/2D Design - [[Inkscape]], [[Corel Draw]], [[AutoCAD]] | ||

*Programming - [[C/C++]], [[Arduino]], [[AVR-C]], [[MATLAB]], [[Python]], [[LabVIEW]], [[Processing]], [[PureData]] | |||

===Last Update=== | ===Last Update=== | ||

--[[User:BLewson|BLewson]] ([[User talk:BLewson|talk]]) 15:12, 28 September 2016 (CDT) | --[[User:BLewson|BLewson]] ([[User talk:BLewson|talk]]) 15:12, 28 September 2016 (CDT) | ||

Latest revision as of 19:42, 15 August 2017

MakerSpace Ninja

Email: blewson@tulane.edu

Phone: (864) 497-1924

LinkedIn: Ben Lewson

GitHub: PercussiveMaintenance

Profile

Bio

I'm an engineer with a passion for making and design. The MakerSpace has been a great opportunity for me to work on projects ranging from musical electronics, to robotics, to medical devices. I love the fact that the space is open to people from all departments and majors. I've definitely learned more from the unique perspectives of our users than I ever could have on my own. Right now, I'm working on writing a library for generating different geometric patterns on the laser cutter, improving my team's biopsy punch design, outfitting more of our marching band with sound reactive lights, and a visually driven drum synthesizer. Feel free to email me if you want to know more about any of the projects I've worked on, or if you want to learn more about the MakerSpace. Or if you want to see what I'm currently coding, check out my GitHub!

Projects Portfolio

- NASA Big Idea Challenge: Project Sunflower

- Links and Downloads:Technical Paper Presentation (Click to Download)

Holy expletive, we won! I'm incredibly grateful for the opportunity to have worked with such creative and talented engineers. I truly can't wait to work with these guys in the future.

The Sunflower is a modular Solar Electric Propulsion (SEP) Tug system designed to transfer cargo from Low Earth Orbit (LEO) to Lunar Distant Retrograde Orbit (LDRO) economically and efficiently.

-

Deployment -

Initial Unfolding -

Unfolded half-array -

Fully Assembled in LEO - Automated Biopsy Punch

-

Bearing fit on DLP print (Looks good!) -

DLP printed helical drive mechanism -

Helix drive mechanism overview -

4 Axis CAM Toolpath for helical drive -

Deflection Analysis of prototype case under typical load -

Gear motor mounted in 3D printed casing -

Needle bearing press-fit into housing -

Test blade in manually driven rotating housing -

Fully assembled demo model -

Cross Section of full CAD model - Laser Engraver

- Videos: Motion Test Sample File Engraving Test

-

The first successful engraving-a simple geometric pattern in wood -

The X-axis carriage of the engraver-Driven by toothed belt and pulley -

All the components of the engraver-Motion is functional at this point -

The X and Y axis with motors mounted-Wires have yet to be sleeved and cut to length -

Stepper driver board with 1 driver installed - Sound Reactive Drum Lights

- Videos: Practice Session Promotional Video Piezo Test (2017 parade footage coming soon!)

- Infinity Table

- 3D Printing

- Laser Cutter

- CNC Mill

- CNC Lathe

- Analog Electronics

- Microcontrollers

- Machining

- Design for Manufacture

- 3D Design - Solidworks, AutoDesk Fusion 360, Cura, AutoDesk Print Studio

- Vector Graphics/2D Design - Inkscape, Corel Draw, AutoCAD

The automated biopsy punch solves the problem of the currently time consuming and inconsistent process of taking a punch biopsy for the diagnosis of melanoma and carcinoma. The CMDX Biopsy Team (Sydney Chestler, Ryan Fishel, Perri Levine, and Ben Lewson) have been developing this technology since 2014, for both the Tulane University Novel Technology Challenge and their respective Senior Team Design projects.

This is what happens when information about the GRBL embedded CNC controller, the discovery that reasonably high-wattage laser diodes are available cheaply on Amazon, and a few hundred dollars all fall into my lap at the same time. It was a really interesting project that taught me quite a bit about CNC control workflows, powering laser diodes, and the joys of 80-20 aluminum extrusion.

As a proud member of the Tulane University Marching Band from 2014 to 2016, I was incredibly excited for the chance to add sound reactive lighting to our drumline to make our Mardi Gras parades a little more exciting and possibly disorientating.

For when you need a side table for your dorm room, but you have a pathological obsession with blinking lights and haven't heard of addressable LED strips yet.