Scot Ackerman MakerSpace at Tulane University Wiki: Difference between revisions

No edit summary |

Themaggiest (talk | contribs) |

||

| (158 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

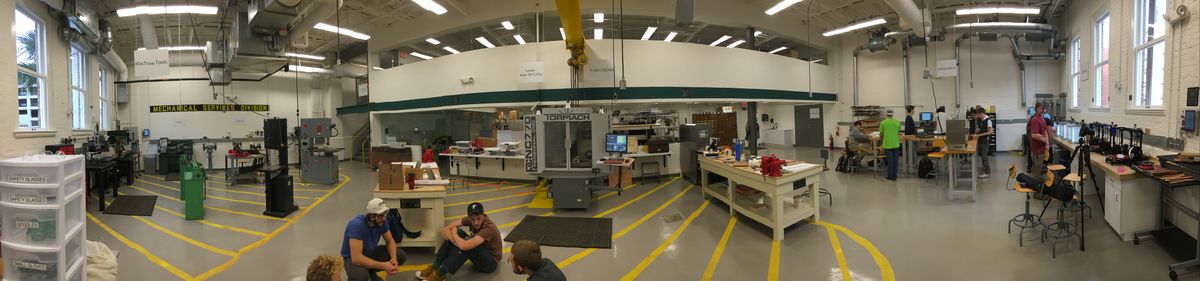

[[File:MakerSpace_pano.jpg.JPG|1200px]] | [[File:MakerSpace_pano.jpg.JPG|1200px]] | ||

A MakerSpace has been [https://placesjournal.org/article/makerspace-towards-a-new-civic-infrastructure/ described] | A MakerSpace has been [https://placesjournal.org/article/makerspace-towards-a-new-civic-infrastructure/ described] | ||

as new amalgam of art, craft, and technology. Our goal is to serve all makers, and potential makers, in the Tulane Community. | as new amalgam of art, craft, and technology. Our goal is to serve all makers, and potential makers, in the Tulane Community[https://www.youtube.com/watch?v=SkjaNtxLUfk&feature=youtu.be]. We do so by providing tools, assistance, and ideas. '''Commercial use of the MakerSpace is not allowed.''' We provide 3D printer filament and laser plywood for ''academic'' and ''personal use projects''. If in doubt, questions about interpretation should be directed to the [[People|Maker-In-Chief or a Director]] before a project is started. | ||

{| class="wikitable" align="right" style="text-align:center" | {| class="wikitable" align="right" style="text-align:center" | ||

|- | |- | ||

!Connect! | !Connect! | ||

|- | |||

|[[File:Microsoft-teams-logo.jpg|85px|link=https://teams.microsoft.com/l/team/19%3a9cd33ae271c44b05a0bb215756799046%40thread.tacv2/conversations?groupId=0a9df3b1-37bc-4544-a5c0-96618e8d55de&tenantId=9de98183-25d9-4b13-9fc3-4de5489c1f3b]] | |||

[https://teams.microsoft.com/l/team/19%3a9cd33ae271c44b05a0bb215756799046%40thread.tacv2/conversations?groupId=0a9df3b1-37bc-4544-a5c0-96618e8d55de&tenantId=9de98183-25d9-4b13-9fc3-4de5489c1f3b Microsoft Teams] | |||

|- | |- | ||

|[[File:Facebook.png|85px|link=https://www.facebook.com/MakerSpace.Tulane]] | |[[File:Facebook.png|85px|link=https://www.facebook.com/MakerSpace.Tulane]] | ||

| Line 17: | Line 16: | ||

|[[File:LinkedIn.jpg|100px|link=https://www.linkedin.com/groups/Tulane-MakerSpace-8483294/about]] | |[[File:LinkedIn.jpg|100px|link=https://www.linkedin.com/groups/Tulane-MakerSpace-8483294/about]] | ||

[https://www.linkedin.com/groups/Tulane-MakerSpace-8483294/about LinkedIn] | [https://www.linkedin.com/groups/Tulane-MakerSpace-8483294/about LinkedIn] | ||

|- | |- | ||

|[[File:Instagram.png|100px|link=https://www.instagram.com/tulane_makerspace/]] | |[[File:Instagram.png|100px|link=https://www.instagram.com/tulane_makerspace/]] | ||

[https://www.instagram.com/tulane_makerspace/ Instagram] | [https://www.instagram.com/tulane_makerspace/ Instagram] | ||

|} | |} | ||

==[[Software#Getting_Started|Just Getting Started?]]== | ==[[Software#Getting_Started|Just Getting Started?]]== | ||

Stop by the Scot Ackerman MakerSpace during operating hours (look at the "MakerSpace Access tab, at left) and ask the student worker in a green apron (we call them Fabrication Technicians or Fab Techs) to walk you through our registration and safety briefing process. You'll need your Splash Card to register. Look at what other users have made, and ask the Fab Tech for advice on your first project. | |||

==Where are we?== | ==Where are we?== | ||

[[https://goo.gl/maps/tNEXdiFUhAS2 Google Map]] | [[https://goo.gl/maps/tNEXdiFUhAS2 Google Map]] | ||

[[https://makerspace.tulane.edu/index.php/MakerSpace_Access Aerial view]] | [[https://makerspace.tulane.edu/index.php/MakerSpace_Access Aerial view]] | ||

If you're using Google Maps, just type '''WVPH+RH''' in the search box. | |||

==When are we open?== | ==When are we open?== | ||

| Line 36: | Line 38: | ||

==News and Updates== | ==News and Updates== | ||

===News=== | ===News=== | ||

* | * 30 Tulane students enrolled in Dr. Katherine Raymond's team design class for biomedical engineers partnered with the nonprofit MakeGood for their service learning project. They designed and produced training wheelchairs for toddlers, called [https://tulanian.tulane.edu/fall-2023/biomedical-engineering-students-team-design-and-make-child-size-wheelchairs mobility trainers], using resources in the Makerspace to 3D-print, laser-cut, drill, sew, and assemble the wheelchairs. | ||

* | * Prof. Nicole Gasparini's students are helping special needs children experience different forms of topography and soil. The project involves using 3-D printers and laser cutters at the Scot Ackerman Makerspace to create [https://news.tulane.edu/pr/tulane-service-learning-class-brings-hands-science-visually-impaired synthetic landscapes] that can be used to simulate volcanoes, tsunamis and earthquakes. | ||

* | * Maker Fab Tech '''Meghan Bush''', interning in NASA's Photovoltaic and Electrochemical Systems Branch, bested 200 other interns to win the first [https://news.tulane.edu/pr/tulane-student-shows-right-stuff-nasa-glenn-research-center-competition GlennTalks Live] competition. Bush won for her project "Characterizing Photovoltaics in a Near-Space Environment." | ||

* | *In August 2018, four Tulane students [https://news.tulane.edu/pr/tulane-team-competes-%E2%80%98world%E2%80%99s-fastest-invention-competition%E2%80%99 represented the University] at the '''Make48 College Challenge'''. The TV show filmed at that event in Baltimore was edited into 10 episodes and broadcast on WYES and WLAE in Fall 2019. You can also stream it. Meet the team from 14:44 to 17:22 of the [https://www.pbs.org/video/301-dki9lk/ first episode]. The team's product pitch starts at 9:41 on [https://www.pbs.org/video/305-zng7td/ the fifth episode] and the winners are announced at 23:05 on the same episode. There's also a brief [https://www.youtube.com/watch?v=CkFhJHyYx68 video clip] featuring the Tulane students, a [https://make48.com/2019/09/tulane-university-and-the-big-easy/ Q&A interview] and a promo for the entire [https://www.youtube.com/watch?v=BGvG6tW1ZZw series.] | ||

* | *Our [https://www.omax.com/globalmax-waterjet/1508 water jet cutter] is in service. David, the factory rep, trained 16 users in two sessions. The machine cuts steel, glass, ceramics, aluminum, and any hard non-porous material. Bring your material and a .dxf or .svg file and the Fab Techs can help you. | ||

* | *The 2019 Burton Morgan Foundation Novel Tech Challenge was won by [https://news.tulane.edu/news/tulane-grads-set-sights-new-orleans-their-startup two Biomedical Engineering students] who developed and prototyped their project in the MakerSpace and are now creating the initial clinical testing production run of their invention on our 3d printers. | ||

* | *Jamie Milstein, a Senior in the Freeman School of Business, came to the MakerSpace a week before a pitch competition, asking our Fab Techs to teach her how to create a full scale model of her product idea. In three days, she learned how to use the 3D printers and made a great prototype. Then, [https://freemannews.tulane.edu/2019/03/27/senior-wins-10k-in-outdoor-weber-business-competition/ she won $10,000]. | ||

* | *The Maker of the Year Award recipient for 2019 is [https://makerspace.tulane.edu/index.php/Lewis_Greenstein Lewis Greenstein]. Scroll down to the photo of his winning submission. | ||

* | *Our new Epilog laser cutter, with a 48"x36" bed, is in place and available. | ||

* | *The MakerSpace is now the [https://news.tulane.edu/pr/tulane-makerspace-be-named-honor-donor-graduate Scot Ackerman MakerSpace], after a generous gift from Scot Ackerman, a 1978 graduate in Biomedical Engineering. | ||

'''[[News Archive]]''' | |||

<!-- | |||

--> | |||

===Maker of the Year=== | |||

The 2021 Maker of the Year Award, funded by [http://tulane.edu/sse/news/alumnus-connects-tulane-to-microscopes-history.cfm a generous gift from Lary Walker (G ’76, ’79)] is presented to Catherine Gilbert and Jorge Nagel | |||

(School of Medicine) for their design of an open-source, 3d-printable, powered air purifying respirator called the Hygieia PAPR (www.hygieiapapr.com). . | |||

<div><ul> | |||

<li style="display: inline-block;"> | |||

[[File:Catherine_Gilbert_and_Jorge_Nagel_1.jpg|400px|thumb|left]] | |||

[[File:Catherine_Gilbert_and_Jorge_Nagel_2.jpg|200px|thumb|right]] | |||

</li> | |||

<br> | |||

Catherine and Jorge describe their work: "This PAPR is a low-cost, easily accessible, just–in–time 3D printable PAPR design that performed above NIOSH and OSHA standards for flow-rate and particle filtration for loose-fitting PAPR devices to be made and used when industry-made designs are unavailable." | |||

</ul> | </ul> | ||

</div> | </div> | ||

===Architecture Laser Cutter=== | <!--===Architecture Laser Cutter=== | ||

The School of Architecture's large format laser cutters are available to MakerSpace users. Currently they charge $10/hour ($3 minimum) for machine time; payable with Splash card or check. They have extended operating hours. Go to http://architecture.tulane.edu/dol/reserve-laser | The School of Architecture's large format laser cutters are available to MakerSpace users. Currently they charge $10/hour ($3 minimum) for machine time; payable with Splash card or check. They have extended operating hours. Go to http://architecture.tulane.edu/dol/reserve-laser to schedule time on one of their three 32"x18" laser cutters. File formats are PDF or Illustrator. As with our Epilog laser cutters, use a line width of 0.001" to vector cut. Be sure to set your document size to their bed size of 32"x18" which is different from the bed size of the Epilogs. Bring your material and files (on a USB drive) to room 104 of Richardson Memorial Hall; student workers are there to help you get set up. | ||

--> | |||

==Links on this Wiki== | ==Links on this Wiki== | ||

[[MakerSpace Access]] | [[MakerSpace Access]] | ||

:Hours, location, and contact information. | :Hours, location, and contact information. | ||

[[ | [[Safety, Trainings, and Manuals]] | ||

: | :Information on safety procedures and training, plus links to instruction manuals for equipment. | ||

[[Available Tools]] | [[Available Tools]] | ||

:Links and information concerning the tools we have in the MakerSpace, grouped by category. | :Links and information concerning the tools we have in the MakerSpace, grouped by category. | ||

[[ | [[Workshops]] | ||

: | :Schedules and information on workshops offered in the MakerSpace | ||

[[Software]] | [[Software]] | ||

:A list of software programs that are available to students, with notes on their use. | :A list of software programs that are available to students, with notes on their use. | ||

| Line 112: | Line 112: | ||

== The New Orleans Maker Community == | == The New Orleans Maker Community == | ||

New Orleans has a long history of artistic creation, and that creativity is now expressed in a vibrant maker community. The Tulane MakerSpace is proud to be a part of this community. Other members include | New Orleans has a long history of artistic creation, and that creativity is now expressed in a vibrant maker community. The Tulane MakerSpace is proud to be a part of this community. Other members include | ||

*[[image:Fablab.JPG|75px]][http://www.dcc.edu/student-services/ | *[[image:Fablab.JPG|75px]][http://www.dcc.edu/student-services/affairs/fab-lab.aspx FabLab NOLA, at Delgado Community College, open to the community]<br> <br> | ||

*[[image: | *[[image:Scale_Workspace.jpg|50px]][https://www.scaleworkspace.com/ Scale Workspace, professional advanced manufacturing services.]<br><br> | ||

*[[image: | *[[image: Real.jpg|75px]][http://www.realized-designs.com/ Real DFM, professional design and production studio]<br> <br> | ||

*[[image:mystic.bmp]][http://mystickrewe.com/ The Mystic Krewe of the Silver Ball] | *[[image:mystic.bmp]][http://mystickrewe.com/ The Mystic Krewe of the Silver Ball] | ||

Latest revision as of 14:50, 2 September 2025

A MakerSpace has been described as new amalgam of art, craft, and technology. Our goal is to serve all makers, and potential makers, in the Tulane Community[1]. We do so by providing tools, assistance, and ideas. Commercial use of the MakerSpace is not allowed. We provide 3D printer filament and laser plywood for academic and personal use projects. If in doubt, questions about interpretation should be directed to the Maker-In-Chief or a Director before a project is started.

| Connect! |

|---|

|

|

|

|

Just Getting Started?

Stop by the Scot Ackerman MakerSpace during operating hours (look at the "MakerSpace Access tab, at left) and ask the student worker in a green apron (we call them Fabrication Technicians or Fab Techs) to walk you through our registration and safety briefing process. You'll need your Splash Card to register. Look at what other users have made, and ask the Fab Tech for advice on your first project.

Where are we?

[Google Map] [Aerial view] If you're using Google Maps, just type WVPH+RH in the search box.

When are we open?

Click on "MakerSpace Access" to see our hours of operation.

News and Updates

News

- 30 Tulane students enrolled in Dr. Katherine Raymond's team design class for biomedical engineers partnered with the nonprofit MakeGood for their service learning project. They designed and produced training wheelchairs for toddlers, called mobility trainers, using resources in the Makerspace to 3D-print, laser-cut, drill, sew, and assemble the wheelchairs.

- Prof. Nicole Gasparini's students are helping special needs children experience different forms of topography and soil. The project involves using 3-D printers and laser cutters at the Scot Ackerman Makerspace to create synthetic landscapes that can be used to simulate volcanoes, tsunamis and earthquakes.

- Maker Fab Tech Meghan Bush, interning in NASA's Photovoltaic and Electrochemical Systems Branch, bested 200 other interns to win the first GlennTalks Live competition. Bush won for her project "Characterizing Photovoltaics in a Near-Space Environment."

- In August 2018, four Tulane students represented the University at the Make48 College Challenge. The TV show filmed at that event in Baltimore was edited into 10 episodes and broadcast on WYES and WLAE in Fall 2019. You can also stream it. Meet the team from 14:44 to 17:22 of the first episode. The team's product pitch starts at 9:41 on the fifth episode and the winners are announced at 23:05 on the same episode. There's also a brief video clip featuring the Tulane students, a Q&A interview and a promo for the entire series.

- Our water jet cutter is in service. David, the factory rep, trained 16 users in two sessions. The machine cuts steel, glass, ceramics, aluminum, and any hard non-porous material. Bring your material and a .dxf or .svg file and the Fab Techs can help you.

- The 2019 Burton Morgan Foundation Novel Tech Challenge was won by two Biomedical Engineering students who developed and prototyped their project in the MakerSpace and are now creating the initial clinical testing production run of their invention on our 3d printers.

- Jamie Milstein, a Senior in the Freeman School of Business, came to the MakerSpace a week before a pitch competition, asking our Fab Techs to teach her how to create a full scale model of her product idea. In three days, she learned how to use the 3D printers and made a great prototype. Then, she won $10,000.

- The Maker of the Year Award recipient for 2019 is Lewis Greenstein. Scroll down to the photo of his winning submission.

- Our new Epilog laser cutter, with a 48"x36" bed, is in place and available.

- The MakerSpace is now the Scot Ackerman MakerSpace, after a generous gift from Scot Ackerman, a 1978 graduate in Biomedical Engineering.

Maker of the Year

The 2021 Maker of the Year Award, funded by a generous gift from Lary Walker (G ’76, ’79) is presented to Catherine Gilbert and Jorge Nagel (School of Medicine) for their design of an open-source, 3d-printable, powered air purifying respirator called the Hygieia PAPR (www.hygieiapapr.com). .

Catherine and Jorge describe their work: "This PAPR is a low-cost, easily accessible, just–in–time 3D printable PAPR design that performed above NIOSH and OSHA standards for flow-rate and particle filtration for loose-fitting PAPR devices to be made and used when industry-made designs are unavailable."

Links on this Wiki

- Hours, location, and contact information.

Safety, Trainings, and Manuals

- Information on safety procedures and training, plus links to instruction manuals for equipment.

- Links and information concerning the tools we have in the MakerSpace, grouped by category.

- Schedules and information on workshops offered in the MakerSpace

- A list of software programs that are available to students, with notes on their use.

- Supplies on hand at the MakerSpace, and where to find them.

- Information about suppliers and other online resources.

- Samples of projects and instructions for doing them yourself.

- Access the digital library for MakerSpace books and resources

- Examples of projects built in the Tulane MakerSpace.

- Information on those involved in building, managing, and improving the Tulane MakerSpace.

MARS (Makers And Robotics Society)

- Connect with the Tulane Makers and Robotics Society.

- Methods for supporting the Tulane MakerSpace

The New Orleans Maker Community

New Orleans has a long history of artistic creation, and that creativity is now expressed in a vibrant maker community. The Tulane MakerSpace is proud to be a part of this community. Other members include

FabLab NOLA, at Delgado Community College, open to the community

Scale Workspace, professional advanced manufacturing services.

Scale Workspace, professional advanced manufacturing services. Real DFM, professional design and production studio

Real DFM, professional design and production studio

The Mystic Krewe of the Silver Ball

The Mystic Krewe of the Silver Ball