Cody O'Cain: Difference between revisions

No edit summary |

No edit summary |

||

| Line 23: | Line 23: | ||

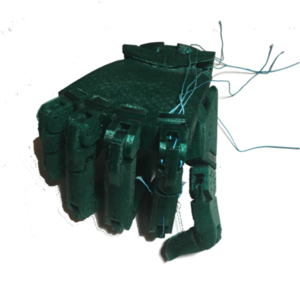

<li style="display: inline-block;"> [[File:Pros 2.png|thumb|none|300px|First prototype after printing (open) ]] </li> | <li style="display: inline-block;"> [[File:Pros 2.png|thumb|none|300px|First prototype after printing (open) ]] </li> | ||

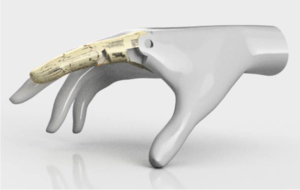

<li style="display: inline-block;"> [[File:Pros 3.png|thumb|none|300px|Rendering of second prototype in development (closed) ]] </li> | <li style="display: inline-block;"> [[File:Pros 3.png|thumb|none|300px|Rendering of second prototype in development (closed) ]] </li> | ||

<li style="display: inline-block;"> [[File:Pros 4.png|thumb|none|300px|Rendering of second prototype with possible elastomer | <li style="display: inline-block;"> [[File:Pros 4.png|thumb|none|300px|Rendering of second prototype with possible elastomer ('skin") covering (open) ]] </li> | ||

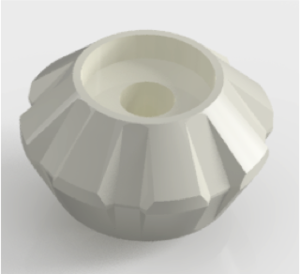

<li style="display: inline-block;"> [[File:PROS 5.JPG|thumb|none|300px|Prototyping with elastomer material for flexible joint movement ]] </li> | <li style="display: inline-block;"> [[File:PROS 5.JPG|thumb|none|300px|Prototyping with elastomer material for flexible joint movement ]] </li> | ||

</ul></div> | </ul></div>) | ||

*'''Biaxial Device''' | *'''Biaxial Device''' | ||

| Line 43: | Line 43: | ||

<div><ul> | <div><ul> | ||

<li style="display: inline-block;"> [[File:CubbF.JPG|thumb|none|300px|All eight drawers in place]] </li> | <li style="display: inline-block;"> [[File:CubbF.JPG|thumb|none|300px|All eight drawers in place]] </li> | ||

<li style="display: inline-block;"> [[File:CubbS.JPG|thumb|none|300px|One of the drawers | <li style="display: inline-block;"> [[File:CubbS.JPG|thumb|none|300px|One of the drawers. I used strips of wood instead of panels to cut down on material]] </li> | ||

</ul></div> | </ul></div> | ||

Revision as of 05:54, 16 November 2016

MakerSpace Ninja

Email: cocain@tulane.edu

Phone: (504) 756-9173

Major: Biomedical Engineering

Profile

Bio

I'm a Senior in Biomedical Engineering who is passionate about product development, finite element analysis, and Biomechanics. The MakerSpace has been a great place for myself, and I encourage anyone reading this to come by and explore! Working in a space open to all students produces ideas that would be impossible in major specific group, and this open environment has allowed me to learn many new, interesting skills. My personal focus is translating MRI / CT files into patient specific mesh files to be used for finite element study, and also 3D printing. I also look for new methods and tricks that can be used to create a broader range of designs with greater complexity from the laser cutters, 3D printer, and PCNC mill.

Projects

- Replicating Human Hand Motion

)

- Biaxial Device

- Sound Stand

- Drawers

- Fixing Sink

- Automated Silly String

- Acrylic Work

Skills:

- 3D Printing

- Laser Cutter

- CNC Mill

- Analog Electronics

- Microcontrollers

- Basic Machine Skills

- 3d Design - Solidworks, AutoDesk Fusion 360, AutoDesk MeshMixer, Cura, AutoDesk 123D Make, Memento, MeshLab

- Graphics - Adobe Illustrator, CorelDraw, Photoshop