Chase Schober: Difference between revisions

No edit summary |

No edit summary |

||

| Line 34: | Line 34: | ||

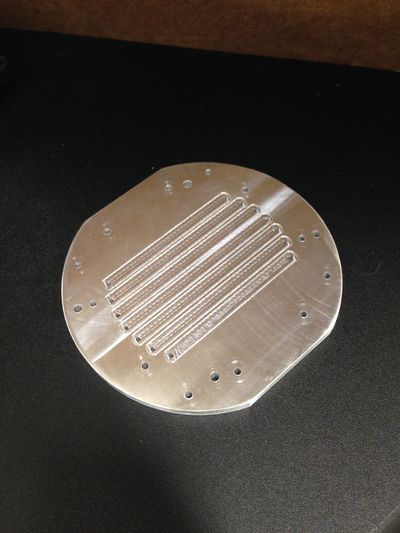

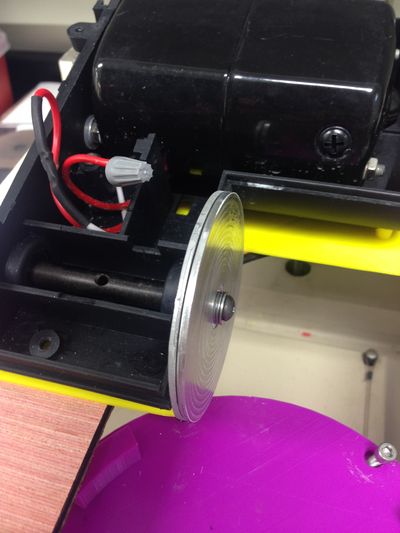

I was approached by this lab at the beginning of the summer and provided them with access to the 3D printers and laser engravers in the MakerSpace. As I began to train on the CNC mill, they took interest in my services and hired me as their lab machinist. The bulk of their demand has been aluminum parts for the Full Spectrum Solar Energy Conversion system they are developing. Below are some of the more complex parts that I have machined for them with a technical description. | I was approached by this lab at the beginning of the summer and provided them with access to the 3D printers and laser engravers in the MakerSpace. As I began to train on the CNC mill, they took interest in my services and hired me as their lab machinist. The bulk of their demand has been aluminum parts for the Full Spectrum Solar Energy Conversion system they are developing. Below are some of the more complex parts that I have machined for them with a technical description. | ||

[[File:Chase Escarra 1.jpeg|400px]] | [[File:Chase Escarra 1.jpeg|400px]] | ||

| Line 44: | Line 45: | ||

[[File:Chase Escarra 5.jpeg|400px]] | [[File:Chase Escarra 5.jpeg|400px]] | ||

| Line 66: | Line 59: | ||

[[File:Chase Jarrod 3.png|400px]] | [[File:Chase Jarrod 3.png|400px]] | ||

Fidget Spinner: | |||

Dice: | |||

Spinning Army Star | |||

[[File:Chase_Star.jpg|400px]] | |||

*'''Laser Engraver''' | *'''Laser Engraver''' | ||

Revision as of 03:51, 17 September 2017

MakerSpace Ninja

Email: cschober@tulane.edu

Phone: (504) 722-9514

Major: Engineering Physics

Graduation Date: May, 2018

Projects

- CNC Mill

Over the summer of 2017, I logged over 300 hours on the Tormach PCNC 770 mill. After training with the available stock in the MakerSpace, I began to machine parts for various research groups on campus. These custom parts varied significantly in complexity and required tolerance. Here are some of the more comprehensive projects that I worked on with a description of their process and purpose.

Tulane University Biomechanics of Growth and Remodeling Lab :

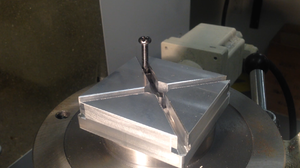

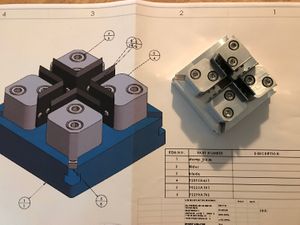

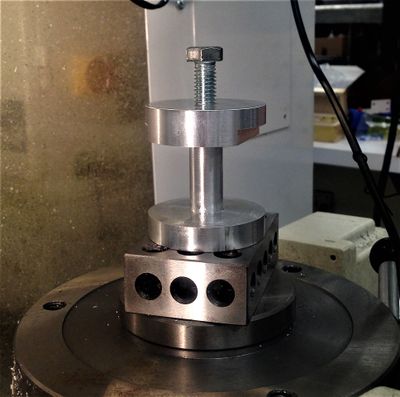

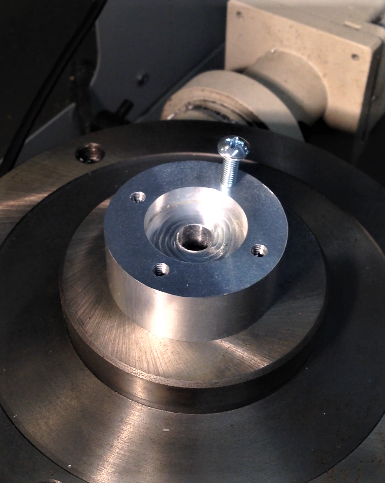

This lab approached me with the engineering plans for an adjustable cruciform to assist in his bio-medical research. They provided me with CAD models of four "slider" parts and one "stamp base". I imported them into Fusion 360, wrote the CAM, and machined the parts using the Tormach PCNC 770. Becuase of the locomotive nature of the sliders, each of their tolerances was ± .002". Each of the stamps required machining on both the top and bottom surface and so were flipped in the vice halfway through the operation. This was an excellent experience in standardizing my measurement procedure and performing the operation so that the two cuts met each other smoothly.

The stamp base required the use of a T-slotter to route the hole for the sliders. I researched the appropriate feeds and speeds of the new tool and manipulated the CAM to produce a cut within specification. This part also required a vice flip in order to machine both sides.

The cruciform, made of the five machined components, is being actively used by the Biomechanics of Growth and Remodeling Lab at Tulane University. Before we came into contact, a machining company had quoted their lab $585.00 for the five parts.

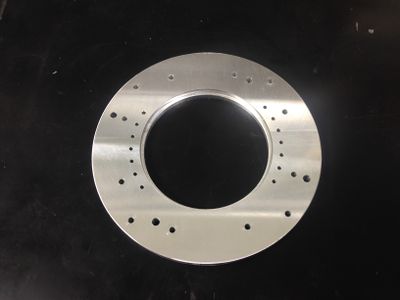

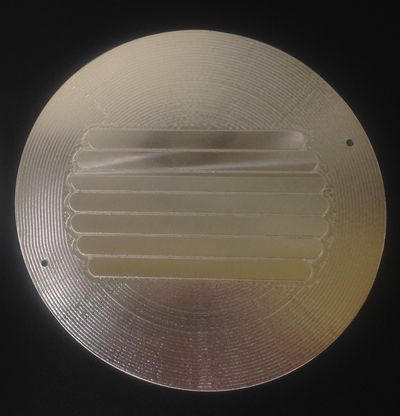

Tulane University Photonic Materials and Device Lab

I was approached by this lab at the beginning of the summer and provided them with access to the 3D printers and laser engravers in the MakerSpace. As I began to train on the CNC mill, they took interest in my services and hired me as their lab machinist. The bulk of their demand has been aluminum parts for the Full Spectrum Solar Energy Conversion system they are developing. Below are some of the more complex parts that I have machined for them with a technical description.

- CNC Lathe

Cryo-Optic Chamber Lid

Jarrod's Parts

Fidget Spinner:

Dice:

Spinning Army Star

- Laser Engraver

Chess Board:

Arduino Enclosure:

Coasters:

Bowling Set: