Jason Schuster: Difference between revisions

No edit summary |

No edit summary |

||

| Line 66: | Line 66: | ||

<li style="display: inline-block;"> [[File:Keyboard stand.JPG|thumb|none|300px|Keyboard Stand]] </li> | <li style="display: inline-block;"> [[File:Keyboard stand.JPG|thumb|none|300px|Keyboard Stand]] </li> | ||

<li style="display: inline-block;"> [[File:Keyboard leg detail.JPG|thumb|none|300px|Keyboard Stand Detail]] </li> | <li style="display: inline-block;"> [[File:Keyboard leg detail.JPG|thumb|none|300px|Keyboard Stand Detail]] </li> | ||

</ul></div> | </ul></div> | ||

<br /> | <br /> | ||

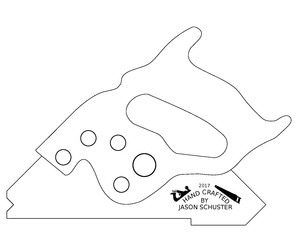

If you would like to make a saw handle push stick for fun or your Wood 1 training, here's the file! I created the vector path from an image I found online, saved it as a pdf, and then laser engraved the image onto the blank piece of wood I was going to use for the training. Note this is not required for the class, I prepared the outline ahead of class. Obviously, you will want to delete or modify my handcrafted logo. Once you start your training, your pattern is ready and you can use the lines for where to cut. Click on the image below and follow the "original file" link to download the PDF. | |||

<li style="display: inline-block;"> [[File:Saw handle push stick.pdf|thumb|none|300px|Saw handle PDF]] </li> | |||

==Exorcist3D YouTube Channel== | ==Exorcist3D YouTube Channel== | ||

Revision as of 04:18, 25 January 2018

Bio

I grew up on a farm, and have been a DIYer, Maker, Fabricator my whole life. I attended the University of Nebraska at Lincoln and earned a Bachelor's in Science in Mechanical Engineering. I then went to industry as a Design Engineer. In 2015, I was looking for a change from Agriculture and Construction equipment to the Biomedical Engineering field, Now at Tulane I am working towards a PhD as a Research Assistant with a goal of staying in academia and teaching new generations how awesome science and engineering is!

If you see me in Makerspace, say hi and introduce yourself, I am always happy to help out.

Outside of Tulane, my favorite activity is cycling, My favorite bicycle race is the Leadville 100MTB, it is an endurance mountain bike race with a 12 hour cutoff, riders must complete a 100 mile course, at an average elevation over 10,200 feet in Leadville, Colorado. My finishing record is 4 for 4. Leadville Race Series website

Jason Schuster

Maker Ninja

PhD Candidate

Department of Biomedical Engineering

Lab Website: Biomechanics of Growth & Remodeling Lab

Email: jschust5@tulane.edu

Maker Skills:

- 3d Printing: Laser Cutter, Lathe, Mill, Woodworking, Sand casting

- Welding: TIG, MIG, Stick, & Oxy-acetylene

- CAD: Solidworks, AutoDesk Fusion 360, Pro/Engineer CREO, Geomagic/Cubify Design

- CAM: AutoDesk Fusion 360, Inventables Easel

- 3D Printing: Cura, Sprinter Firmware, Slic3r,

- Graphics: Inkscape, Adobe Illustrator, Adobe Photoshop, GIMP

- Programming: LabVIEW, MATLAB, Mathematica

- Makerspace Training Certifications:

- Learning: Slicer for Fusion 360, blender

Tulane Makerspace Project Portfolio

If you would like to make a saw handle push stick for fun or your Wood 1 training, here's the file! I created the vector path from an image I found online, saved it as a pdf, and then laser engraved the image onto the blank piece of wood I was going to use for the training. Note this is not required for the class, I prepared the outline ahead of class. Obviously, you will want to delete or modify my handcrafted logo. Once you start your training, your pattern is ready and you can use the lines for where to cut. Click on the image below and follow the "original file" link to download the PDF.

Exorcist3D YouTube Channel

Here's my YouTube channel, several videos of my 3D printer and South Bend lathe are found here:

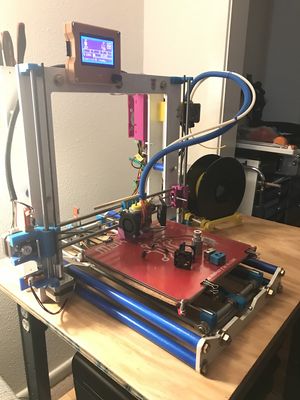

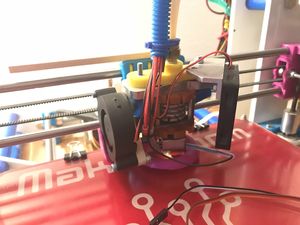

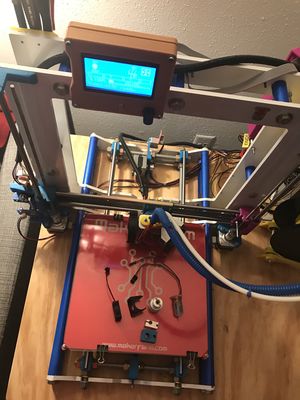

OpenSource 3D Printer

In 2013, I built my own opensource 3D Printer. I modified the Prusa i3 design. Controlled by: Arduino Mega + RAMPS 1.5 with Sprinter firmware. The frame is made from 1/4" laser cut steel plates and 3/4" lathe turned rods. The build surface is heated and 10" x 10" x 10". Recently, I made several improvements and upgrades, which include a large screen graphical LCD with SD card reader and a genuine E3D titan extruder. Future upgrades include a BL Touch auto bed level and 1.75mm E3D V6 Nozzle.

Several of the parts I printed in the Makerspace: * Tan LCD display box * Purple X-axis belt tension bracker * Purple Arduino & Ramps box * Purple Printer cooler fan shroud

1934 South Bend Lathe Restoration & Projects

Over Christmas break 2017, I machined some small parts for my lab. These parts are cannula, used to mount soft tissues on our inflation-extension test device. The material is PEEK plastic, it can be auto-claved and machines nicely. Check out my YouTube link above, there is a quick video of the PEEK being machined. The lathe I used is a 1934 Southbend 9" Workbench 405. This lathe is a restoration project I completed in 2010.

Last Update

JasonS 17 January 2018