Jason Schuster

Bio

I grew up on a farm, and have been a DIYer, Maker, Fabricator my whole life. I attended the University of Nebraska at Lincoln and earned a Bachelor's in Science in Mechanical Engineering. I then went to industry as a Design Engineer. In 2015, I was looking for a change from Agriculture and Construction equipment to the Biomedical Engineering field, Now at Tulane I am working towards a PhD as a Research Assistant with a goal of staying in academia and teaching new generations how awesome science and engineering is!

If you see me in Makerspace, say hi and introduce yourself, I am always happy to help out.

Outside of Tulane, my favorite activity is cycling, My favorite bicycle race is the Leadville 100MTB, it is an endurance mountain bike race with a 12 hour cutoff, riders must complete a 100 mile course, at an average elevation over 10,200 feet in Leadville, Colorado. My finishing record is 4 for 4. Leadville Race Series website

Jason Schuster

Maker Ninja

PhD Candidate

Department of Biomedical Engineering

Lab Website: Biomechanics of Growth & Remodeling Lab

Email: jschust5@tulane.edu

Maker Skills:

- 3d Printing, Laser Cutter, Lathe, Mill, Woodworking, Sand casting

- Welding: TIG, MIG, Stick, & Oxy-acetylene

- CAD - Solidworks, AutoDesk Fusion 360, Pro/Engineer CREO, Geomagic/Cubify Design

- CAM - AutoDesk Fusion 360

- 3D Printing: Cura, Sprinter Firmware, Slic3r,

- Graphics - Inkscape, Adobe Illustrator, Adobe Photoshop, GIMP

- Programming - LabVIEW, MATLAB, Mathematica

- Learing - Slicer for Fusion 360, blender

- Makerspace Training Certifications

Tulane Makerspace Project Portfolio

Exorcist3D YouTube Channel

Here's my YouTube channel, several videos of my 3D printer and South Bend lathe are found here:

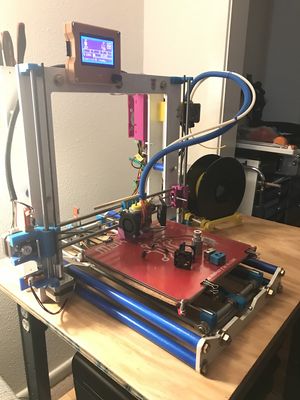

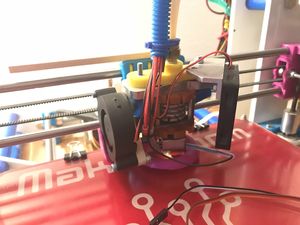

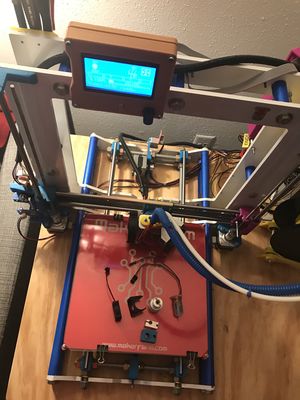

OpenSource 3D Printer

In 2013, I built my own opensource 3D Printer. I modified the Prusa i3 design. Controlled by: Arduino Mega + RAMPS 1.5 with Sprinter firmware. The frame is made from 1/4" laser cut steel plates and 3/4" lathe turned rods. The build surface is heated and 10" x 10" x 10". Recently, I made several improvements and upgrades, which include a large screen graphical LCD with SD card reader and a genuine E3D titan extruder. Future upgrades include a BL Touch auto bed level and 1.75mm E3D V6 Nozzle.

Several of the parts I printed in the Makerspace: * Tan LCD display box * Purple X-axis belt tension bracker * Purple Arduino & Ramps box * Purple Printer cooler fan shroud

1934 South Bend Lathe Restoration & Projects

Over Christmas break 2017, I machined some small parts for my lab. These parts are cannula, used to mount soft tissues on our inflation-extension test device. The material is PEEK plastic, it can be auto-claved and machines nicely. Check out my YouTube link above, there is a quick video of the PEEK being machined. The lathe I used is a 1934 Southbend 9" Workbench 405. This lathe is a restoration project I completed in 2010.

Last Update

JasonS 17 January 2018